Lancaster Flow Automation

Lancaster Flow Automationdesigns and manufactures premium high-performance production chokes for use in the most rugged oil & gas field environments.

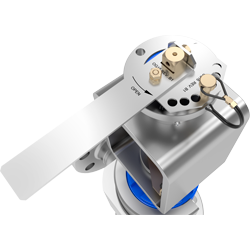

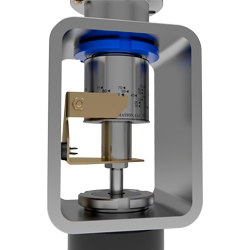

Lancaster chokes are versatile, compact and durable. The extremely low operating torque eliminates the need of large hand wheels, cheater bars or multiple personnel to adjust the choke. Automation can be accomplished with any electric multi-turn, linear, pneumatic, or hydraulic actuator.

Learn more

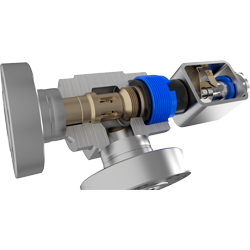

Lancaster chokes contains fewer moving parts than most industry designs. This results in less wear and tear and extends the period between maintenance cycles. Our chokes have interchangeable components and provide exceptional resistance in erosive conditions.

Learn more

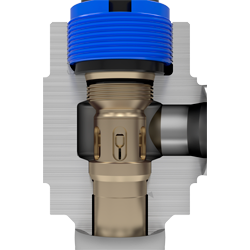

Lancaster chokes are engineered to operate at high pressures and process aggressive fluids containing sand and other solid particles. Our manufacturing processes and selection of materials ensures maximum resistance of all components extending the service life of the choke.

Learn more

The Lancaster manufacturing facilities are located in Houston, Texas and Samarinda, Indonesia. We have a service and maintenance facility in Abu Dhabi and sales offices in Singapore, Jakarta, Kuala Lumpur, Islamabad, Melbourne and Muscat.

Learn more

14041 West Road, Suite 100

Houston, Texas 77041 USA

14041 West Road, Suite 100

Houston, Texas 77041 USA