CA CHOKE VALVE SERIES

TECHNICAL DATA SHEET FOR MAXIMUM TRIM SIZE OF 1.18”

CA CHOKE VALVE SERIES

TECHNICAL DATA SHEET FOR MAXIMUM TRIM SIZE OF 1.18”

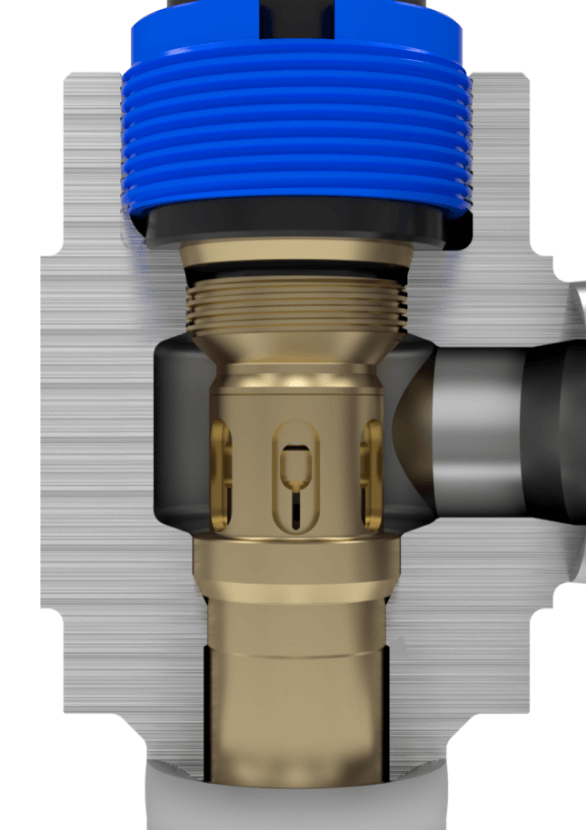

The ‘CA’ product family of production choke valves utilize a 0.75” to 1.18” orifice and offer the ability to manually or remotely control well production flow at the wellhead and or flowline with a more conventional type choke body. The cage & plug flow trim is pressure balanced to minimize the stem loads and provide low operating torques. Standard end connections range in size from 1” to 4”.

| Design | CAGE & PLUG | NEEDLE | CAGE & PLUG |

|---|---|---|---|

| TRIM SIZE: | 0.75” | 1.00” | 1.18” |

| CV: | 11.2 | 27.0 | 26.5 |

| MAX BEAN SIZE: | 48/64 | 64/64 | 76/64 |

| END CONNECTION: | CUSTOMER SPECIFIED | ||

| VALVE MODEL | CA |

| BODY TYPE | Right Angle |

| BODY SIZE | Suitable for max. 1.18” orifice |

| BODY RATING | 15,000 psi (max.), Limited by the rating of the body end connection. |

| INLET CONNECTION | See ‘End Connection’ table below |

| OUTLET CONNECTION | See ‘End Connection’ table below |

| BONNET TYPE | Lancaster Proprietary Bonnet |

| BODY / BONNET MATERIAL | See ‘Material Options’ table below |

| STEM MATERIAL | See ‘Material Options’ table |

| SEAL MATERIAL | See ‘Material Options’ table |

| TRIM STYLE | Equal Percentage Cage and Plug or Needle |

| BALANCED / UNBALANCED | Balanced |

| FLOW CHARACTERISTIC | Equal Percentage or Linear |

| TRIM MATERIAL | See ‘Trim Options’ table below |

| DESIGN CV | See the table above |

| LEAKAGE CLASSIFICATION | ANSI/FCI 70-2 Class IV (Standard) |

| API SPEC. 6A MATERIAL CLASS DESIGNATIONS | ||||||||

|---|---|---|---|---|---|---|---|---|

| Temperature Class | Certification Level | Material Class Designations | ||||||

| AA | BB | CC | DD | EE | FF | HH | ||

| P-U -20F to 250F -29C to 82C |

STD/PSL-1 | BB | BB | FF | EE | EE | FF | HH |

| PSL-2 | EE | EE | FF | EE | EE | FF | HH | |

| PSL-3 | EE | EE | FF | EE | EE | FF | HH | |

| L-U -50F to 250F -46C to 121C |

STD/PSL-1 | EE | EE | FF | EE | EE | FF | HH |

| PSL-2 | EE | EE | FF | EE | EE | FF | HH | |

| PSL-3 | EE | EE | FF | EE | EE | FF | HH | |

NOTES: other temperature classes are available upon request

| BB-GENERAL SERVICE | EE-SOUR SERVICE | FF-SOUR SERVICE | HH-SOUR SERVICE | |

|---|---|---|---|---|

| RECOMMENDED SERVICE | General Oil, Corrosive (CO2) |

Sour (H2S) Low Corrosive (CO2) |

Sour (H2S) Corrosive (CO2) |

High Sour (H2S) High Corrosive (CO2) |

| BODY | Carbon Steel (60K) Low Alloy Steel (75K) |

Carbon Steel (60K) Low Alloy Steel (75K) |

Carbon Steel (60K) Low Alloy Steel (75K) |

Clad Low Alloy Steel Corrosion Resistant Alloy |

| BONNET | Carbon Steel (60K) Low Alloy Steel (75K) Stainless Steel (75K) |

Carbon Steel (60K) Low Alloy Steel (75K) Stainless Steel (75K) |

Carbon Steel (60K) Low Alloy Steel (75K) Stainless Steel (75K) |

Clad Low Alloy Steel Corrosion Resistant Alloy |

| STEM | AISI 17-4PH Low Alloy Steel |

AISI 17-4PH Low Alloy Steel |

Inconel 625 or Inconel 718 |

Inconel 625 or Inconel 718 |

| PLUG/CAGE ASSEMBLY | AISI 17-4PH Low Alloy Steel w/TCC |

AISI 17-4PH Low Alloy Steel w/TCC |

Inconel 718 w/ TCC | Inconel 718 w/ TCC |

| SEALS | PTFE/PEEK | PTFE/PEEK | PTFE/PEEK | PTFE/PEEK |

NOTE: The materials supplied may change based on the customers NACE service designation (i.e.- “x.xx- NL”)

| Connection Size | Working Pressure psig | Dim. Ref. | A Outlet | B Inlet | C Manual Operator | D Mounting Flange |

|---|---|---|---|---|---|---|

| 1.00” (25.4) Nom. Orifice (Adj.-Pos., 64/64 Linear Needle or 76/64 EP Cage), Max CV = 26.5 | ||||||

| 2” NPS, RF | ANSI 600 LB. | 7.62 (194) | 7.62 (194) | 20.03 (508.76) |

18.50 (469.90) |

|

| 3” NPS, RF | ANSI 600 LB. | 8.00 (200) | 8.00 (200) | |||

| 4” NPS, RF | ANSI 600 LB. | 10.75 (273) | 10.75 (273) | |||

| 2” NPS, RTJ | ANSI 900 LB. | 8.75 (222) | 8.75 (222) | |||

| 3” NPS, RTJ | ANSI 900 LB. | 8.75 (222) | 8.75 (222) | |||

| 4” NPS, RTJ | ANSI 900 LB. | 11.25 (286) | 11.25 (286) | |||

| 2” NPS, RTJ | ANSI 1500 LB. | 8.81 (224) | 8.81 (224) | |||

| 3” NPS, RTJ | ANSI 1500 LB. | 9.94 (224) | 9.94 (224) | |||

| 4” NPS, RTJ | ANSI 1500 LB. | 11.31 (287) | 11.31 (287) | |||

| 2” NPS, RTJ | ANSI 2500 LB. | 8.75 (222) | 8.75 (222) | |||

| 3” NPS, RTJ | ANSI 2500 LB. | 9.38 (238) | 9.38 (238) | |||

| 4” NPS, RTJ | ANSI 2500 LB. | 11.62 (295) | 11.62 (295) | |||

| Connection Size | Working Pressure psig | Dim. Ref. | A Outlet | B Inlet | C Manual Operator | D Mounting Flange |

|---|---|---|---|---|---|---|

| 2-1/16” (52.38) | API 5,000 | 6.89 (175) | 7.99 (203) | 20.03 (508.76) |

18.50 (469.90) |

|

| 2-9/16” (65.09) | API 5,000 | 8.19 (208) | 9.33 (237) | |||

| 3-1/16” (77.79) | API 5,000 | 9.69 (246) | 9.57 (243) | |||

| 4-1/16” (103.19) | API 5,000 | 10.12 (257) | 12.64 (321) | |||

| 1-13/16” (46.04) | API 10,000 | 7.68 (194) | 8.82 (224) | |||

| 2-1/16” (52.39) | API 10,000 | 7.68 (195) | 8.82 (224) | |||

| 2-9/16” (65.09) | API 10,000 | 8.19 (208) | 9.33 (237) | |||

| 3-1/16” (77.79) | API 10,000 | 7.80 (198) | 8.94 (227) | |||

| 4-1/16” (103.19) | API 10,000 | 9.82 (252) | 11.50 (292) | |||

| 1-13/16” (46.04) | API 15,000 | 8.46 (215) | 9.65 (245) | |||

| 2-1/16” (52.39) | API 15,000 | 8.86 (225) | 10.32 (262) | |||

| 2-9/16” (65.09) | API 15,000 | 10.51 (267) | 11.73 (298) | |||

| 3-1/8” (79.38) | API 15,000 | 10.35 (263) | 11.61 (295) |

* “C” and “D” shown with 3” x 2” reduced orifice trim

1. Using our 24vDC actuator shown, “E” is 11.97”; Pneumatic & Hydraulic units are also available as well as other

Electric units

2. For sizes or dimensions not shown, for ANSI flanges or hub connections, contact sales or engineering

3. In addition to “C”, provide clearance for bonnet and trim removal as follows (worse case – with trim in fully

closed position): 1.0” (25.4) Nominal, add 7.81” (198.37) for needle trim; add 6.75” (171.45) for cage trim

4. (xxx.xx) dimensions shown in parenthesis are in millimeters (mm)

5. Orifices in X/64ths are openings with the equivalent area of a circle with the diameter of X/64ths of an inch;

64/64ths = 1.00”

6. API 5,000 psig is equal to 34.473 MPa; 10,000 psig = 68.946 MPa; 15,000 psig = 103.420 MPa; 20,000 psig =

137.893 MPa.

7. Dimensions shown above are subject to change without notice. Other dimensions are available, please consult

the Lancaster engineering department.